Our Other Warehousing Services:

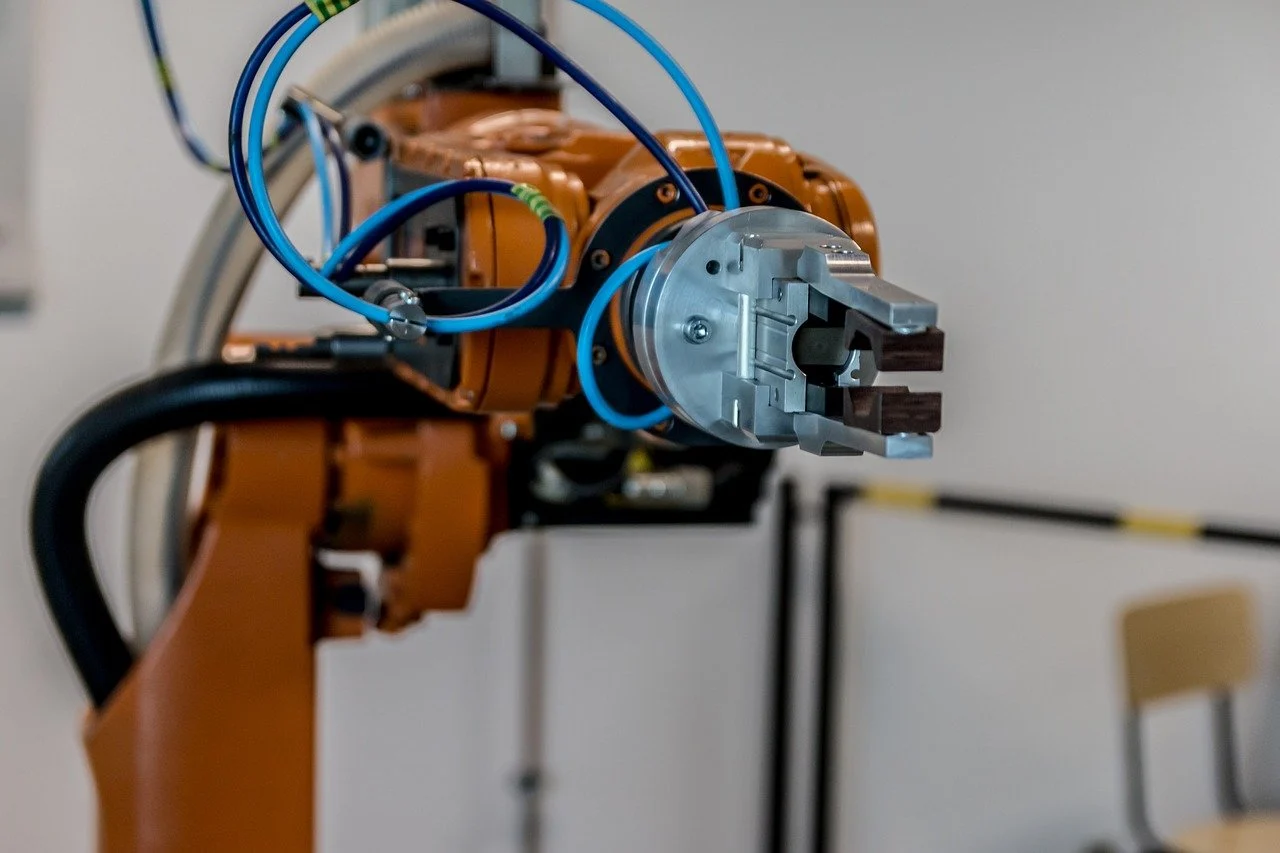

Automation and Robotics

Automation and robotics are transforming operations, offering practical solutions to today’s business challenges. Once seen as complex and costly, advances in sensing technology, responsive safety systems, AI, and cloud-based solutions have made automation more accessible than ever.

Technologies like goods-to-person systems, robot picking, collaborative robots (cobots), and autonomous mobile robots (AMRs) are now within reach for businesses of all sizes. These innovations provide greater flexibility, scalability, and cost-effectiveness, empowering companies to optimise productivity and meet growing demands with confidence.

Now is the time to explore how modern automation can drive efficiency and unlock new opportunities for your business.

Our Approach

LPC has long experience with automation in devising an automation strategy and designing solutions, assisting with procurement and contracts and implementation support including:

Strategy and Potential Options:

Given the ever widening range of automation and potential options, it is sensible to consider your strategy, whether a phased approach or partial or full automation is the optimum solution for your operation. The strategy should take account of growth and potential future developments.

Validation of Options:

There may be a variety of potential solutions for your operation containing either partial or full automation, each with differing capex requirements and opex. The costs and benefits should be calculated for each and for the conventional option to determine the optimum solution

Tendering and Contracts:

An organised approach that determines interest and capability from potential suppliers followed by a comprehensive tender or RFP/RFQ that clearly sets out your requirements and performance expectations generally work best. When you have identified your preferred partner, the contract needs to be agreed and the detail worked out and agreed. This should include the performance criteria and the testing schedule to demonstrate that it is delivered as well as the usual programme and payment terms. It is best to use an engineering contract rather than a construction form. Any requirement for maintenance and support should be identified and agreed at this stage.

FDS and FAT:

Successful automated projects depend on getting the functionality to support your operation. It is very important that the functional design specifications (FDS) for the automation cover the setup and configurations you require and that the acceptance tests (FAT) are thorough.

Implementation:

While the system is being delivered the planning for takeover, occupancy, training and go live and run up should be developed and any operational support identified. The project is not complete until you are in a steady state operation.

Growing sales, new store openings, or supply chain challenges? LPC International helps you adapt by re-engineering facilities to boost storage, optimise workflows, and reduce costs. We can extend the life of existing sites or plan for future expansion—often eliminating the need to relocate.

Book a healthcheck today to turn growth challenges into opportunities.

Read Our Blog

5 Essential Features To Look For In a WMS Platform

Today’s warehouse management systems (WMS) can perform a wide array of functions to boost efficiency and profitability. However, when selecting a WMS, it’s crucial to choose one that will perform the tasks you need it to and have features you’re going to use.

How Does Fixed Asset Tracking Work In Warehouse Management?

The term “fixed assets” refers to assets that your company owns, which generally stay in the same location, such as your land or buildings. However, these assets also include the delivery vehicles in your fleet and intangible assets, such as software and cloud storage.

Automation Isn’t Just A Solution – It Is A Journey

The interest in automation is increasing under the impact of changing supply chains, labour availability/scarcity, the perennial drive to improve productivity and efficiency, and order response times.